Our team can assist with the supply, installation, and repair of industrial and mining valves, pumps, and pipe fittings.

Industrial and Mining Valves, Pumps, and Pipe Fittings

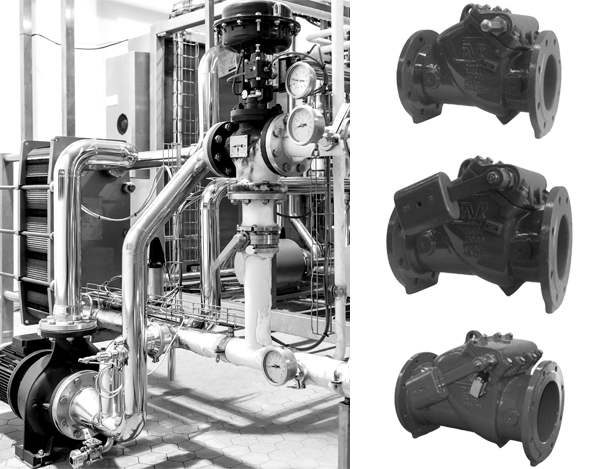

Industrial and mining valves are mechanical devices designed to regulate, control, and direct the flow of fluids (liquids, gases, or slurries) within industrial processes and mining operations. These valves play a critical role in controlling the movement of materials through pipelines, ensuring efficient operation, and enabling safety measures. Industrial and mining valves come in various types and configurations, each designed for specific applications and conditions.

Industrial and mining pipe fittings are components used to connect and redirect pipes in various configurations within industrial and mining applications. These fittings are crucial for creating a reliable and efficient piping system that can withstand the demands of heavy-duty processes and harsh environments. Industrial and mining pipe fittings come in different shapes, sizes, and materials, and they serve several purposes, including altering the direction of flow, connecting pipes of different sizes, and providing access for maintenance or instrumentation.

Key aspects of industrial and mining valves

Industrial and mining valves are integral components in a wide range of applications, including oil and gas processing, chemical manufacturing, power generation, water treatment, and mining operations. The selection of the appropriate valve type depends on factors such as the nature of the fluid, pressure and temperature conditions, flow requirements, and safety considerations within the specific industrial or mining process.

Key aspects of industrial and mining pipe fittings:

Industrial and mining pipe fittings are essential components in the construction and maintenance of piping systems, contributing to the overall efficiency, safety, and reliability of fluid transport within industrial facilities and mining operations. The correct selection and installation of pipe fittings are crucial to ensuring the integrity of the entire piping system.